Lumbering

The log receiving side of the saw mill had as much of a colorful part to play as the raft side. The illustration of the Grand Rapids Lumber Company saw mill at Grand Rapids was typical. The logs came to the pond and were hauled up the slide to the second and sawing floor.

Many mills installed what they called their "hot pond". The simply meant that they run a steam jet or a line of hot water into the pond to keep it free of ice all winter, which greatly facilitated the better handling of the logs. The early mills and especially those that owned timber lands from which their logs could be floated down to the mills, used the river to bring in their stock of logs in the spring. Later, the mills, whose timberlands were along the railroads, shipped whole train loads of logs to their mills. Lumber camps were established in the timber and men worked out of these locations.

The buildings were generally built of logs cut on the spot to form a clearing. Sleeping bunks were built onto the sides of the sleeping shanty, generally two bunks high. All were heated with wood stoves with the stove pipe running up through the ceiling and about the roof, often a source of fires. Eating houses combined the cook's quarters and dining room for men and many times it was the "community house" for men in which to congregate. The tables, for the dining room, were of plain boards, many feet long and about six feet wide. The benches furnished the seats and they were one board wide and ten to sixteen feet long.

The foreman of the camp was the supreme head. Crews often numbered into the hundreds and under different organization than the smaller ones. Men hired out in the fall and stayed in camp all winter, coming out either during the log drive in the spring or by rail. They seldom ran summer camps. Roads, because of rains, would be bottomless and flies and mosquitoes would eat men and horses and oxen alive. Men in the logging camps were called "lumber jacks" and often reminded one of the Canadian "voyageurs". Many of the early camp followers really did come from Canada.

The hours were from twelve to fifteen a day. They were called in time for breakfast at six o'clock, a lunch was sent out to them at nine and another at three and supper when they got into camp anywhere from nine to eleven.

In the early camp days the main bill of fare was salt pork, navy beans, and flour. Molasses was added and later dried fruit especially prunes. "Flapjacks" were a luxury and a special inducement offered the men. Coffee and tea and sugar finally found their way as the competition between camps grew stronger. Their camps that were in active operation in the early ninety's and later served meals that would rival any good hotel. Pie, cake, doughnuts appeared on the breakfast bill and fresh meats served in many forms three times daily. Many managers stated that it was cheaper and more satisfactory to fill up their men with sweets than meats.. Liquor was never allowed in the camps though occasionally a little came in especially with new arrivals but that did not last long. The average pay was fifteen dollars a month and board.

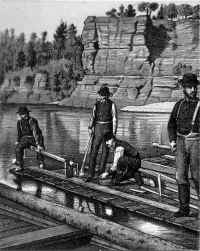

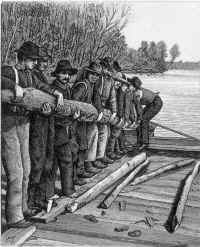

Logs were cut from twelve to twenty-four feet in length. The longest ones were for special orders and many were greatly in excess of this were intended for bridge purposes. Trees were chopped down first in most camps. After being felled, men with cross-cut saws cut them to standard lengths. The logs were all marked with two brands. One was the end mark made with a maul, on the face of the head were raised letters or emblems, and the other was cut with an ax on the side of the log. Logs were banked at the river edge and often on the ice to await the breaking up in the spring. When the log drive began, either a boom company crew took charge of the drive or the owners sent their crews. The picture shows the usual batteau that the men used in their log drives. The logging companies were crowding their crews and greater logging operations in the wood were demanded.

The illustration page 129 shows a load of logs which were being hauled, to a mill outside of Grand Rapids some fifteen miles to Vesper. This load contained 16,520 feet on a scale of one inch board measure. They made these loads possible by making an ice track for the sleds to run in. These tracks were cut out with a plane-like tool set in the runner and this cut a trough, then it would be followed by a tank and water poured into the track.

The mill is shown in the illustration also. These logs were hauled to the mill pond and rolled in and logs taken from the pond up a log slide to the carriage floor and there sawed. This lumber was then loaded onto small cars and pushed out into the yards and piled for seasoning.

The lumber that "went down the river" went into the rafts fresh from the saw mill. On the way down the river, the drive would encounter booms across the river in different series and in the center of these would be a "sorting works". This would be a set of gates and as the logs came down to this gate the drivers would pike pole them into the different gates according to their log marks. Some booms would carry their individual owners logs direct to their several mills, while logs intended for farther down the river would be run into the main gate out into the main channel to encounter similar sorting works farther down. This sorting was done by the boom companies chartered for that purpose.

LOG MARKS

Relative to log marks. The State of Wisconsin was divided into four inspection districts.

First - East of the 4th Meridian and North of line between township 30 and 31.

Second - West of the 4th Meridian and North of the line between township 30 and 31.

Third - West of the 4th Meridian and South of township 30 and 31.

Fourth - East of the 4th Meridian and South of the township line between 30 and 31.

The law provided for inspectors for each district. Number One was located at Rhinelander, district number two at Ladysmith, number three located at Eau Claire and number four at Stevens Point. The statutes provided that a person could have recorded a diagram and complete written description of the log mark in the office of the inspector for the district within which he wished to use it. Using marks not recorded and using any mark which was recorded by any other person within the same district was prohibited. Destruction of or effacing such marked called for s evere penalty.

evere penalty.

By another section - all persons floating logs on the Wisconsin River or its tributaries were required to place recorded marks upon each district through which the logs were floated, and notice of the marks given to the booming companies. There was a penalty for having in possession logs belonging to others whose marks were recorded.

On the Wisconsin River, at Rhinelander, the Pelican Boom Company was formed in 1822. Through the courtesy of this boom company these old records were obtained. The following are some of the marks of various lumber companies whose logs passed through the boom company's sorting works.

Brown Brothers Lumber Company used various marks, some of which were "S22" - "BB", an emblem formed by an open diamond enclosing "JO", equilateral triangle enclosing the figure "6", a square enclosing a figure "8" capital letter "Y" with a downward hook to the upper right hand branch of the letter, "HZL" but the "Z" was made as if pulled out featuring a tall "S", capital "A" with an eight spoke wheel within a rim.

Scott Lumber Company, end mark was a triangle enclosing the letter "S" and a side mark would be "VXV" another was an open triangle and side mark "N" with "K" formed on the right hand side of the upright part of the "N".

Gilkey and Anson used a side mark of "L" enclosing the plus sign "I" and end mark of "O", also a sidemark combination of "YK" and end mark "O".

Menasha Wooden Ware Company us an end mark appropriately one of the outline of a pail enclosing the capital letter "A", also "GOAT", also "333", also "INK" also "HSV" "LII", "MAY" and other marks meant for special mills also into whose booms they wished their logs guided.

John Farrish, Grand Rapids, used an open five point star enclosed within a circle and a further smaller circle with the star and within that the letters "XF".

John Edwards and Company of Port Edwards, used the "JE" the "E" joined on the base of the "J". The side or water mark was deep cuts like the outside lines of "H" enclosing an "X" called and "X" girdle. This was the second oldest mill plant on the Wisconsin River. First built in 1836 and sold to John Edwards Sr. in 1841. There were many escapades in these camps and many good stories originated in them.

One of the most grotesque was where the winter camp became buried in snow so deep that no one could get away from the camp for several weeks during which time one of the lumber jacks died. The deep snow and intense cold prevented taking the body out. Saturday night was carousal night and restraint was lifted. For three successive weeks they brought their dead frozen companion in and held a wake in his honor. When midnight came, they returned him to his berth in the outside shed. There was nothing disrespectful in this, they felt their companion should, even if he couldn't participate with them in the "Irish" wake celebration.

Gene Shepard invented the "hodag" for the entertainment of some tenderfeet who had never heard a screech owl and were "nearly scared to death". Gene told them that is was a terrible animal and was called by him on the spur of the moment a "hodag". Gene made a preposterous horned animal, small bear in size, and planted it and by skillful handling let them discover it in the woods. Many and resourceful were the pranks played that would be entertaining if collected. So have passed one of the most history making epochs of any state.

An Overview of Rafting

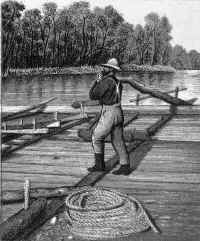

The following set of pictures shown are from actual scenes along the Wisconsin River during the run of a fleet of lumber and a description of these rafts as they were built up is interesting. More so because the present generation has not no possibly ever will see anything like them.

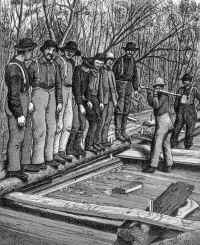

Binding planks parallel with the first planks underneath were fastened onto the grubs shown in the next illustration called "witching" or drawing tight the layers of lumber and fastening tight with a wedge run through the grub pin. This crib usually contained about four thousand feet of lumber. Six or seven of such cribs were fastened together tandem fashion, by coupling planks and this was called a "rapids piece", shown in the next illustration.

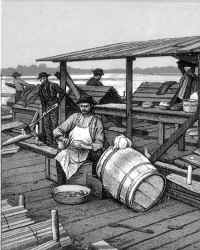

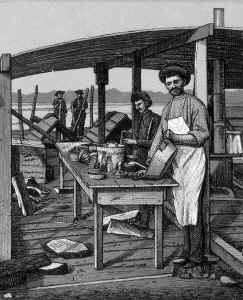

Two "rapids pieces" fastened together made a "Wisconsin Raft" and several such rafts comprised a "fleet of lumber", sometimes containing much as a million feet. To properly operate the "Wisconsin raft" it required at least ten bowsmen and ten tailsmen together with a pilot and steersman. When required all hands jumped into the water and with long heavy poles lifted the rafts off the sand bars. From Grand Rapids to St. Louis might require six weeks. On these rafts were built the cook's shanty and the "dog-houses" as sleeping cabins for the me

When the rafts passed through towns where there was some population there were always a lot of young fellows waiting at the various eddies for a chance to run the rapids with the crew and when the water was not too dangerous this permission was granted, to the great delight of the boys.

Usually the ice went out of the river between the first and fifteenth of April and the log driving and running of the rafts began then

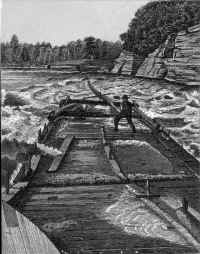

The dams were required to have log slides built in them at the natural course of the river. These slides were a part of the dam but the crest was at least two feet lower than the rest of the dam. The slides were provided with an apron built down stream and it was often a dangerous operation to guide a raft through these slides, for at the bottom it would duck under the water, and the men likely to be washed off but for the sucker-line. This apron often extended at the foot of the slide and was made of logs fastened at the slide with the lower end free to float. Grand Rapids was a rapids of importance to the drivers. There was about a mile of this water but with high water it did not take over five minutes to make the run.

Just below Grand Rapids was an eddy where the rafts tied up and the crew "gigged back" above the rapids to bring down another raft. This "gigging back" process was repeated after the raft had passed each swift rapid where only one piece could be brought down at a time. So the progress down the river until the crew reached Whitney Rapids was a succession of repeated miles.

Testimony of Louis Schultz

Louis Schultz said he was eighty-three years last month. That he was born in 1856 right in the town of Portage and still remained there.

"I have been acquainted with the Wisconsin River from Kilbourn years ago when I used to be hop picking in 1868, a young lad, between there and Kilbourn. That was just a rowboat. Then from Portage to Prairie du Chien, I was there steady for the three years, 1875, '76, '77 and part of '78. I was running an engine, firing an engine on a government steamboat.

In 1871, they started to build the wing dam system on the Wisconsin River from Portage to Prairie du Chien, to make that stream navigable in that section. In 1871, they started in at Portage and at Merrimac. In 1872 they started three crews; down at Lone Rock, and Merrimac and Portage. Then they started to build three steamboats, the government did, right there at Portage, to convey the material for these dams; that is, brush and stone.

My boss at that time – his name was Captain John M. Nader, from New York. In 1872 I was – when I started there – well, I will just go right along, because otherwise I will get it mixed up. In 1872, in the spring of the year, I started to work for Captain Nader. The government office at that time was in Portage. There was another man who was his assistant, who was John Pierpont; and the head clerk was Horace K. Rice.

Captain Nader wanted to hire a man in his office as an office boy, and I was recommended. Somebody told me about it, and I got the information and saw the captain, and he hired me.

In the middle of the summer I commenced to get sick. In them days there was an awful epidemic of malarial fever. It used to be every year in the south, that malarial fever, and it got as far up as up in Wisconsin. Well, at intervals, I would get so sick that I couldn't attend to my work; so in the fall, when it froze up, they moved the office to Madison, Wisconsin, and I didn't go along because I couldn't stand it, the fever was too bad. He wanted me to come down there, he was satisfied with my work.

So the next spring, the first of April, he came up for to hire a bunch of men to work on a wing dam, Captain Nader did, came from Madison. And I was informed in the evening that Captain Nader was there, and he hired some men to go down to Merrimac to start work at Merrimac on the wing dam. So I made it a point to see him at the hotel, and I did see him, and he appeared to be very pleased to see me.

"Why", he said, "Louis," he says, "it is too bad," he says, "that I didn't see you during the day". He says "I would certainly want you along down there tomorrow, but", he says, "nevertheless I only have orders from headquarters to hire twelve men."

He started in cutting brush, to have the material on hand when the work crew got going in a couple of weeks, so that they would have material on hand, such as mats, mat brushes, ten, twelve, sixteen feet long; and stone also.

I said, "All right, I will go if you will give me a chance." So we had to go through down by the Low Dive to get to Merrimac, because the river was so terribly high at that time.

We got to Merrimac, the next morning, and we started to work right across from Merrimac; and I was not there only about two weeks when I got the ague again.

So Captain Nader made his first investigation about two weeks after we started, and there was a steamboat, Portage. They had chartered the steamboat Portage, which was a side wheeler, at Portage. The government had chartered it to tow these mat scows, which were about thirty or forty feet wide, and about sixty or seventy feet long, and to haul the stone with from Wildcat Bluff. That is, I should judge, about fifteen miles below Portage. Well, there was another quarry there. There were two different contractors, and each one had his quarry. Well, then, we went – we hauled acme (sic) of the stone there to the ground.

And I got over the ague, and Captain Nader came there for an inspection, and he seen me sitting on the quarterboat. We had a large quarterboat, holding about seventy-five men, boarding the rooming them, you know. And he wanted to know how I – he was in the cabin of the Portage, the steamboat, and he wanted to know – he saw me sitting there – it was after supper, and he motioned over to me to come up there, and I went over to the steamboat and he says "How are you feeling, Louis?"

I said, "I have gotten over the ague pretty well. I don't know how long it will last. You know how it worked on me last year."

"Yes" he said, "you certainly had a bad siege of it. Nevertheless," he says, "the water is a very poor place for ague; that is where the malarial fever starts down south during the summer, around the Mississippi River."

He says, "You come down to Madison, to the Madison office Monday. We are going up to Portage, and whenever you get ready, come down to Madison and work in the office."

And so I did. I was then two years and nine months at Madison, working in the office for Captain Nader. Our office was right in Main Street, opposite the Park Hotel. I was transferred back to Portage on a steamboat that they had built, a stern wheeler they called the Decorah. They built three of them for hauling material, such as stone and brush, and to tow these scows from one place to another.

Well, I was transferred back on the steamboat at Portage, this Decorah. I remained there for that season. I worked, that is, I did and our crew, worked from Portage, out of Portage down as far as Merrimac. Then the other crew worked at Honey Creek Flats, that is this side of Prairie du Sac, and then down at Spring Green and down further; and the third crew, they started that spring.

I never worked there, but we went down with our Decorah, because it was a very light draft boat, to take soundings, and we took soundings about five or six times in one season, and we sent them reports on to Washington. We continued that way for two or three years. Then Captain Nader would always come up about once a month to make an inspection.

The dam was built from the shore, and the first part of it went up against the stream. Then this end you laid down-stream, so as to give the water a shoot, to get rid of that sand, if there was any way of trying to do it, because that was the trouble, the hard thing to do with; and the only thing to do, we thought, with the sand that standing in the river from Portage to Prairie du Chien.

Well, we worked at that and put in the dams all along. We had orders from headquarters, through Captain Nader, that if at any time we had time, to give any aid to the raftsmen, to aid the raftsmen to get through, on account of these sand bars, which today would be here and tomorrow would be there. The sand rolls just through that water, that was quicksand. There is not any river that I know of where there is such floating sand, such a degree of quicksands, as there are in the Wisconsin River. A pilot never knew where a sand bar was going to be the next day. We had pilots from all over the country and they said they never seen anything like the Wisconsin.

The first course of the dam would be lapped with a course of mats. Those mats were generally from six feet, according to the size of the brush — if it was long brush, why, they would be longer mats, twelve or fourteen feet long. Otherwise the oak brush would not be so long, they would be eight or ten feet, and about six feet wide. Then there were poles put across this way about eighteen inches from each side, on the bottom and on the top, and then they were bound through with marlin cord.

A "marlin" is a cord that has a tar filling, and that keeps out the water. That marlin would last for years in the water there. And then they would go to work and put the first course down. The other one they would lap over part way, and they would throw stone — there was one large barge of stone and one barge of brush, of mats. They would go to work and have a stone crew and a mat crew on these barges.

They had poles they would put in according to the depth of the water in the river wherever there would be these dams. Some places they would go down ten or fifteen feet; in other places probably only a foot or two; but they would always protect the bottom so that the water would not wash underneath them, because that would spoil the dam. Then they would put a course of stone right on top of it. Every course of mats would require a course of stone. They would build them up, well, in a normal way, about two feet above the water; so when it is high water they handicapped the raftsmen that were running rafts down the river.

We were all a good deal under the impression that the Wisconsin River was navigable even Captain Nader, but it was only a couple of years afterwards when Captain Nader was changed to Washington, and he came and made an inspection from Washington, and they found it was a different proposition than they thought.

That evening Captain Nader told me in a conversation we had, when were talking about old times in Portage, when he was living there, and I was in the office, and he said "Louie, I used to think we could make the stream navigable, but we can't make that stream navigable any more than a dog can use two tails". He said, "I will guarantee you that we can't."

And it came true, and he gave it up then, and when he gave it up, another man, Mr. Hinman, a captain or lieutenant, Hinman, took over the job, and they thought they were going to make it navigable. They both died a long time ago. Now, he didn't do any more than Captain Nader did.

Captain Nader said, "The only thing we can do with it is to build a wall on both sides and fence it in."

That is the only thing we can do with that river, because you can't and no one can do anything else with it, anything with sand. The sand is just the same as the water. It seems impossible for sand and as coarse as that sand to roll in the water, as heavy as that sand is; but that water and that sand work together.

Anyone can go out and stand on a sand bar that is just out of the water about two inches, and inside of an hour he will be up to his knees in that quicksand. I know, because I worked there; and time and again, when the captain was tired, and everything else, I says, "Cap, I am going to take a spar out to the line". We were caught there over the sand bar, and was trying to get across. I would take it out for him because he was an old man. His name was Captain John Stevenson. He is dead long ago now. This was in 1874 – no, in 1875.

Probably some of you people have heard of the old Fort Winnebago at Portage. We got all them stones that all them building were built with. They were all stone buildings in the fort, and there naturally was a good many of them. Some fellow, I did know at the time what his name was, bought all of these buildings and sold them to the government for the stone, because it costs quite a little to quarry them. These were already quarried, and they hauled them to the river bank right there at Portage. Then with the steamboat we took them down to the works, wherever we were.

Some days we go down the river with the expectation of being back to the quarterboat up here at Portage to get our supper, and probably we wouldn't get back until ten, eleven or twelve o'clock that night, on account of these bars. We would strike these bars.

When we went down, the current was here, the channel one place; and when we came back, it was way over in another. It changed that way.

I can tell you an instance – we had an order, I think I mentioned it before, from the government quarters, through Captain Nader, that when it was anywhere reasonable that we should give the raftsman aid. Well, this evening a pilot was laying up at Merrimac, and he come up to the boat and he wanted to know if the captain was there. I was then firing this steamboat, a side wheeler. And he wanted to know where the captain was. He was sitting up the pilot house, just got through with his supper. And he wanted to know if he could see him. I called up to the captain, Captain Clemens, who lived then at Burlington, Wisconsin, and he came out. He knew Captain Clemens, George Marsh, the pilot of this 14-raft fleet.

He said they had saddle-bagged the pier at Merrimac. What I mean by saddle-bagged, here is your pier or the bridge, built with a great heavy rail. We didn't know anything about cement in them days. Here are the rafts and when he got up here, there was a very deep channel underneath that bridge at Merrimac, underneath the Merrimac bridge; very deep today, more so than it was, because this lake from Prairie de Sac up to Decorah, within eight miles of Portage, that is all lake, clear to the dam at Prairie du Sac. Well, he saddle-bagged the pier in this way with his rafts.

Well, we turned the steamboat around and we went down and threw a towline, and they fastened the towline, and they said "all right," and we commenced to pull. Just as soon as we commenced to pull we made the current so much stronger, and the rafts went down, part of the rafts went down and the rest shot right up here on the top of this pier.

The three boats, the Merrimac, the Decorah, and Boscobel; they were all built the same year, stern wheelers, so as to give them ample room. They were used mainly for hauling supplies and material, these mats or stone to the place where we were working. When they were unloaded, no load in them, they drew six inches in the bow, and eighteen inches on the stern. The wheel and the engine made that difference. But when they were loaded with stone or brush on the bow, it brought that down and brought the stern up. That made them, when they were loaded, with the usual load, draw twenty inches. We didn't dare to load over twenty inches because we would strike sand bars.

When it was empty, coming home, we did not get stuck because it was so light it was built so light. The engine was light and the boiler was light. That was all the weight we had on it. But if we had a load on we got stuck, because the weight of the stone, and with a full hull seventy - five feet long, it will not take much to put it down in the water.

Testimony of Gustave A. Giese

Gustave A. Giese was next witness. "I will tell about log driving, so that you will get a pretty good idea of what is in the course of a day's work. When the logs are cut in the woods – the trees are standing growing, and they are cut down to specific sizes, twelve, fourteen, eighteen feet, according to the agreements made with the lumber buyers. These logs are loaded on sledges. They are hauled to the banks of creeks; or it is possible, if the creek is froze over, they can drive with that load of logs directly on there. They start right on the bottom, and have skids underneath them, and unload the logs on those skids. They call them rollways. When they get to the bank of the creek, or the river, as the case might be, they clean off the bank, any underbrush or timber that grows, so they can extend the rollway that they started on the creek, out on the bank. They keep on hauling those lots to the bank, and raising the filling up the rollways. Sometimes they have rollways twenty or thirty feet in height, and eighty rods up and down the creek.

In the spring of the year, before they get ready to drive, they make this wannigan, which is a raft made out of hewed timbers, made out of a whole tree. A lot of companies will take a square timber of certain length, where the lengths run from thirty-six to forty feet, and they make the wannigan, which is hewed timber. They have no saws to shape that in the woods, and they take smaller trees and also pine, and hew them down to six by six size, and lay it right on the ends of it; this being the wannigan here (indicating); laid down on the ends, one in front and one behind, and holes bored through, large wannigan sticks, and that is all fastened together. You build a little bit of a wooden shanty. A wannigan will never be any wider than twelve feet on the outside, because it has to follow the men that are driving the logs. For that reason it must be heavily made, because it has to go over boulders and knock up against them; and be narrow enough to follow down the narrow creek.

In the middle of that we have a house where the cook does the cooking. It is a shanty, especially put up, possibly seven or eight feet in width, and maybe ten feet in length. That is all there is. That is where the cook has his general headquarters; and he has a wannigan box, in which he keeps the socks and supplies for the boys who are working there. They would buy up a bunch of tobacco and soap, and so on, and they carry it right in that place. That wannigan always goes behind.

When you get the crew together, you roll your logs, when the ice is gone, roll your logs off the rollways, and keep watching that your logs don't jam, and keep right after them. They have to watch and see that the logs go down and get in the channel, and get moving before the water goes away, because the river runs north and south and the water runs away fast. When your water runs away from them, they jam up the logs. That is a log jam, that sometimes goes across the river from bank to bank. Finally the logs are in such shape that it will hold the water back, and there is a pressure of the water as it accumulates; and when they have a little head, not much higher than that table there, they just bust that jam. They call it a jam break. They go to work and tear out the key log, and they all roll slowly down and keep on going. If they don't run, they probably have to do the same thing in five or six miles, maybe two miles, or maybe ten miles down below. That is the way they do.

They run these logs through the sawmills, where they are supposed to be cut. If it is a nearby sawmill that ships the lumber, and it is made into a raft which comes down the river.

If they have sufficient water, there is no trouble then to keep rolling the logs off the rollways and letting them go down. All we have to do is to let go them go down. We have a few men on the creeks, watching on the banks, to keep the logs going, to see that they don't jam up. If the water is too high, they scatter and go into the woods. Sometimes I have had to take them and move them ten or fifteen and sometimes twenty rods. We don't take them on our shoulders. We take our peavies. You know a peavey, it is a canthook, we grab one on each side. There are four men, and each has his peavey stick, one on each side; two in front and two behind, rolling the logs, and snaking them out, as the case might be. The men attending to that part of the work, they call them suckers.

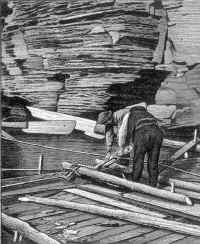

The rapids at Wisconsin Rapids and any other rapids that I had to run over I shall describe. It is almost impossible to tell it section by section, or even greater sections, but in order to get over the first thing, I can start at the very beginning, where the first plank is laid down in the water in order to raft lumber or get the lumber into a raft. We have to build a crib first. The smallest unit of a raft is known as a crib. It is sixteen feet square. You use three grub planks in the bottom, which answers the purpose of runways. It takes three grub planks, two by ten inches sixteen feet long, with holes bored in each end, ten inches from the end, and one bored immediately in the middle of the plank. That gives three holes; those on the end, ten inches from the end of the plank, and one directly in the middle. You get three of those planks, and lay them at equal distances, about eight feet apart; not just eight feet apart, let us say about seven feet and six inches apart. On that you put a tie board, one by six, with holes bored similar to the ones you have in the grub plant, You make the tie boards and the grubs at the same time, by laying one on top of the other. Here you have the grub made, and you take the tie planks, and lay them alongside the bored holes, opposite each. Here are the tie boards and here is the grub here Indicating), That is two-inch stock, that is, this grub here, that goes into the end of that grub plank. You have the hole reamed on the underside so the grub will fit in there this way (indicating); so you can pull this stick clean through. You put that through from the underside, and you put the tie plank over this way (indicating). Then you take a little "witch", the "witch" comes down just like my little finger and that goes into that grub and then the tie board, and sets that "witch" directly into the grub, and you carry that pin down this way, bending it over like this (indicating) and that "witch" will never work out by the up and down action of the raft itself or the lumber itself. If we had driven it between the board and the grub, it would gradually squeeze itself, and your grub will drop; putting it in this way (indicating) it holds it tight, and it will never work out.

And now, having your three grub planks, you begin to pile your lumber crossways. It is in the water now. Then you swing around and you put your first course on, and you lay your second on there like that (indicating); you take another course, and lay it right across until you get clean through, and then you swing your raft back the way it was in the first place, and it stands up and down with the stream. Then you take one or more six-inch boards and put it on top of your lumber, two courses of boards. You set it on top of your lumber, two courses of boards. You set it right on there. Then you have a lever that works this way and keeps all the lumber together by pressing it together like this.

When the crib is done, we "witch" it with those crib sticks. You have an instrument something like a wagon jack, which is a lever. So you all may know what it looks like (illustrates with pieces of paper). That is it. This is the fulcrum. We set that right on our raft this way. The hook, this ring, we slip that right over the grub. It is square, it is not round, and we bear down on this.

One man stand here and pulls that down. It pushes down on the "Witch" plank and the other pulls up on it. The distance from here to there is eighteen inches only, and the distance here is ten feet. You get an awful leverage on it. Every grub we figure that there is five-hundred-forty pounds pull.

I don't know why that gives such extreme power, but it does. They have to be very tight. When the crib is down, two men will manage that crib. It will contain 6,144 feet of inch lumber.

It takes two men to build a crib like that, and when it is all built it will have 6,155 feet. It takes seven cribs to make a rapids piece. Then it takes three rapids pieces to make a Wisconsin raft. In a Wisconsin raft you have in the neighborhood of 135,000 feet of lumber, taken care of by two men clean down to St. Louis, with the exception of where you go through dams.

They must go down in the water, and when half of the cribs are done, the pilot goes down in a rowboat – we call it a skiff – to ascertain the proper current of the water. If the dam is so high he can't get close enough to put the boat down, he portages it around them, and he goes down below and places himself in line, picks himself out some point down below, and says it must be in a straight line, or come down this way, or else he will smash them up. That done, he comes back and selects possibly five men for the bow, and five men for the tailmen. They need that power there to be able to handle a raft with sufficient rapidity to handle it right. One or two men would not amount to nothing.

Before we go down, we have a sucker line that is fastened along the cribs, an inch and a half rope tied on the corner right there. We take a two-inch cable and lead it in under there, and manipulate that rope so that it works underneath the rapids piece, hitched here on the corner of the grub with a double hitch. We handle it over to this corner and manipulate it so that it comes out at this end and take that rope and hitch it here again. We do that cornerways. That is for the purpose, when the raft does go down – we take, for instance, a twenty-foot board, and set it up against the partition like that; and as you go over the dam, there is rocks in the bottom of the river, and while she is in that position, that brings the upper end up right there. For that reason we have those ropes underneath; and when it comes down it presses down, and the harder it presses down the harder it goes in place. Possibly you run fifty or sixty feet all underwater by the drop over the dam; and it stands to reason, taking 120 feet of rafts going down and striking the bottom of the river, it must run an awful long ways before it comes up. Before we go down we take off the front oar and leave it in the pin, and take the tail end of the raft, and hitch a rope to the oar stand and also hitch it to one of the grubs on the end; so that we can each go and select a plac

When they get down below in deep water, those two men with the front oar let it out. They have to steer. In the meantime the men that handle the oar on the tail end of the raft will have to use it to see that the raft runs straight. The quicker they can use their oar, the safer they are, because there are rocks and boulders in the river. I have seen a lot of rafts break up.

These rafts carry a top load of shingles in bundles, and laths in bundles; and tamarack poles. I assume they used them for posts. They are eight feet long and six inches in diameter, square timber. We couldn't very well mix them in with the inch timber. The company I was working for sawed two kinds of lumber; dimension stuff on the west side of the river and the inch lumber on the east side of the river. Each kind made a particular raft. One was running inch lumber altogether, and the other two-inch lumber; but both crews at the time I was there both carried posts, laths, and shingles; put up in four by four, six by six, six by eight, ten by sixteen, put right on top. We carried that on top; and fastened it with the ropes from the cribs, so that when we got under water they would not float off.

That was run down to the mouth of Four-Mile Creek, four miles below Wisconsin Rapids, until all the lumber was down there.

When the last raft came down, they made a shanty for the cookery, and got the flour and ham and provisions of all kinds on it, and we would go right down.

Nekoosa, or Whitney Rapids, never bothered us. If there was water over the Clinch Dam or the South Side Dam, we kept on running and get on until we got down beyond Grignon Bends. That is below Nekoosa, at Germain.

Of course, the river was so winding, you might as well call it the duplicate of an intestine of a hog. That is the way it was. We would keep on rolling around through there. That is just the first day's work, to get through Grignon Bends.

It took two days from Four-Mile Creek. After the lumber was all run over the dam, we congregated there at Four-Mile Creek. The lumber was run in there, and we coupled it and made Wisconsin rafts out of the rapids pieces. It would be two days after you left Four Mile Creek before you got down to the Dells. (see page 121)

I heard the other day a remark by one of the men as a witness. He referred to a brush fence. That created a little merriment. I want to tell you what a brush fence is. That interfered with the running of the Wisconsin rafts, with 135,000 feet of lumber. Originally it was a pile of brush that was left from cutting wood on the banks of the Wisconsin, and when the water rose it carried that out into the river. It either rolled this way or floated in laterally. It kept on floating down until one of the roots caught on to something and it stayed right there. After it stays there for five months you can't dislodge it any more. The sand keeps accumulating under it, and you might call it a beaver dam. You understand what is meant by a beaver dam.

Now, that is the moving of the rafts. I don't know that there is any use of my describing it, because it has been thoroughly discussed here in the last few days. I want to say this much; that from Wisconsin Rapids to the mouth of the Wisconsin River it took us fourteen days to run, which is about two-hundred miles distance. You run about fourteen hours a day. We used to get started at five o'clock in the morning and tie up at seven in the evening, or start in the morning at six o'clock and tie up about eight, which would give us fourteen hours run.

Now, it is common knowledge that a raft normally in the spring of the year will float at the rate of three and a half and four miles an hour. Now, the two-hundred miles from the Rapids to Prairie du Chien would give us fourteen miles a day, the run that we had, an average or one mile per hour running the raft on the river. Accordingly that should make fourteen miles a day.

We had more than four-hundred miles on the Mississippi, and we rafted the four-hundred miles on the Mississippi faster than the two-hundred miles on the Wisconsin, because there were no obstructions. The speed of the raft in normal operations is usually a little slower than the speed of the water.

We never experienced very much trouble between Yellow Banks and the head of the Dells, because it was early in the rainy season, and we had a fair supply of water. In going through the Dells we disconnected our rafts. Where formerly two men handled a Wisconsin raft, consisting of three pieces, four men would take one piece through the Dells, run it through below Kilbourn, and gig back. That is, walking back through the Upper Dells. I suppose it is a distance, if I remember right, of about five miles. We will be all day running that lumber through the Dells, and by the time that the last raft comes through, the first raft is possibly almost right opposite Portage, which is about ten miles below.

From Portage down to Boscobel. The water was unusually shallow there. If we could run that strip we could get out the Wisconsin, and if we couldn't we were hopelessly stuck. We had to wait for a freshet, anywhere from one and one-half to two inches of rainfall. We had to stay right there, or we would be caught again. That was the most narrow piece we had. The hundred miles down to Muskoda, that is the worst piece, where we had to do handspiking, and we had to be in the river a great many hours a day.

I don't know that there is any use in describing that because the present generation is not going to run any more lumber. If I explained it, a lot of you wouldn't understand it unless I made a remarkable explanation of it.

I want to add this much. On the Wisconsin we tied up every evening. The first raft that tied up would try to get a solid tree, or anything else that we could tie to. The other rafts that would come along would tie up in front of him , and in that way we would have five Wisconsin rafts in a string. The next five would tie on the outside of the first five, and leave a space between of about a foot, between the two rafts. In between them two strings of rafts—the five would be about six hundred foot in length – we would throw a little log in there that was fairly nice and round, four foot long, called a "Dutchman" in between the two sets of rafts; because during the night one raft would work up and the other work, down; and this log would be rolling between them, takes the place of a finger, like, so the lumber couldn't batter itself by rubbing up and down.

The rear end into the deep water by making the front end stop. The oarsman is here and he turns the whole raft around suddenly, and the raft will run tail end ahead, until they get to good water, and then they will swing it back again, because it runs the other way faster. It works like this. They have spring poles that work like this. That is the reason it works faster, because the front of the crib has been lifted so as to allow the raft to work that way. In order to get the spring pole in we have to put a log about ten inches wide right at the inside here on the front of the crib.

Speaking of the Wisconsin raft, on the underside of the head block on the front crib – they have it in the back and the front – we have a head block, which is a piece of sawed timber, sixteen feet long, six by ten inches, with notches out in the middle of that head block; between the center grub and the corner grub there is a tamarack pole, thirty-five feet long, sharpened on the thin end a little bit; fixed directly under that head block. The spring pole is brought back to the outside of the center grub, the second grub, and a hole bored right through that, and that spring pole is lifted up over that – wait a minute, I will get it here – get it down in that shape.

Now, we have run all the way through, we are down to the mouth of the Wisconsin. We stop right now because from Bridgeport down the Mississippi there is plenty of water.

Referring to navigation, with respect to commerce running up and down at the time I was running rafts on the river. I saw a boy once in a while with a row boat probably catching some fish. As far as transporting commerce, a good pair of mules would be better. It would be better if you used pack mules there, because in that way you will be safer than running your stuff up the river. Up to Boscobel you probably might meet a little light scow, or a flat bottomed boat, but that is the biggest thing you would see.

Up on the Wisconsin River and down below, there is no commerce, because up above the bottom is too rugged, too full of stones, and down below there is that everlasting accumulation of sand that will never stop. The government naturally has got a great many resources, and they can show what they have done on the Mississippi but they can't do on the Wisconsin what they have done on the Mississippi. They got a channel down there, but it wouldn't be a paying proposition for them to put a channel in the Wisconsin River. No commerce of any kind would go up and down, unless the commerce was lumber. We had to take the lumber down the Mississippi River, and we had to take it down the Wisconsin River, because we had to sell the lumber, because it was no good where we lived, it only represented a value after we got it down the Mississippi.

No one that had any amount of lumber to run would undertake any other time than in the spring of the year, when we had most of the water on hand, while the snow was melting. That was the only time in which we would ever try to run a raft. Before you ran a raft you had to transform that lumber into a crib and raft. If you couldn't do it on the spring raises, if you can't get going in the spring, there was no use of building the cribs, it is better up there on piles than it is in the river.

I have been down to St,. Louis several times, and down to Dubuque half a dozen times, and practically a week later the Wisconsin from Portage clear down to near Bridgeport, almost down to the mouth of the Wisconsin River, was that low so that the lumber was left there and rafted in October. We are more apt to have sufficient supply of water in the way of rain in the fall, than in the middle of the summer.

We get into difficulties on the spring freshets with water getting away, not having enough water. The State of Wisconsin runs north and south and drops possibly six-hundred feet in elevation. About that. So naturally that water will run down that way. It is a big drop there, so it just naturally runs down in the natural way. As soon as it runs down, don't you see, it will dry up below, and you can't even run a row boat. I know at Merrimac at one time we had the river covered completely with rafts from one side of the river to the other. I presume the distance is not less than six or seven hundred feet in width. There was no us of trying to run any further, we just tied up side by side, in hopes that by doing that we would create some sort of a dam, like a jam of logs, but once you got a substantial amount that ran away, there was no use of doing anything.

I never saw government boats on the lower Wisconsin . Rafting ceased in the summer of 1888. The last lumber that went down the river from Wisconsin Rapids was in the month of June, and the lumber belonged to John Farrish. Jack Starr was on that. The present generation will never run any rafts out. It is the new order of things. This pine will all be used, as far as that goes, for the paper mills. There is no interest any more in the growing of hardwood timber up there. It is pine that we are interested in. We had diseases in our hardwood lumber, and we are not interested in anything else but pine. We are not interested in hardwood; if we have anything along the line of pine, we are interested in that.

Consequently, all the pine that is grown now and in future times will not be marketable, will not be sold as wood, it will be sold for paper. The farmer will not even get a chance to buy any red brush.

Even if we had the timber we would not put it on the river, because they have other ways of handling the timber which are easier and cheaper. They have the railroads, and they will never use the river again for rafting. But the pine that we have now, that will be used by the paper mills. And by the time we get any more timber, by that time we will have airplanes that can carry several thousand feet, so the river will never be used again or that.

Possibly a hundred rafts go in a season. They would leave from Grand Rapids, or they would leave from Germantown, which was right at the mouth of the Yellow River. The early years from 1882, Wausau would be the highest point upstream.

Nothing was ever taken in a raft down from Merrill. The first raft taken out of Merrill, busted, and it was scattered all over, and the owner had a heavy expense trying to save his lumber. They made a scow, loaded it up, and tried to send the scow down the river, or the lumber with the scow ahead. They gave up that idea by the time the railroad got there.

From Whitney Rapids at Nekoosa; the river is more or less filled up with boulders, clean up to Grandfather Falls. That is below – above Merrill. It was on those boulders that the scow busted up. Above Grandfather Falls it is all rocky. Nobody ever tried to raft from above Grandfather Falls. They logged it up there, drove it down in logs to Merrill or Wausau. They had their log drives there and took the rafts down from below because there is no sense in rafting lumber in rafts out of that rocky territory.

A great many lumberman worked their way back on the Mississippi, on the packets. They came as far as they could, and they walked it. A great many of them never came back until it began to snow, and naturally they had to track back over the log roads, and then they would turn around and go through the same performance again. That is the only way we had of making money in them days."

Questioned further as to lumber and rafts Mr. Giese said, "Rafts would be made of up from the approximately green timber, when the sawyer sawed the logs that came off of the banks of the river. It was the logs cut off of the stump at the same time as the other logs. Some might be driven down in the log drive, floated down to the sawmill, the other was sawed where it was in the sawmills handy, near the timber. That lumber was hauled a distance of twelve miles for an average of sixty cents a thousand.

Lumber was cut in the nearby sawmills, in a radius of twenty miles. The sawmills – that lumber was sawed in the sawmills sometimes within twenty-four hours from the time that the tree was cut off the stump. In twenty-four hours it had gone through the sawmill. That lumber was hauled by sled from those nearby sawmills, and that lumber went out that spring, each spring.

The number of men that would go all the way down on the rafts depended on the size of the rafts. We had to have at the least calculation seven or eight men. A Wisconsin raft would be four or five hundred feet long in length. Each Wisconsin raft, one hundred twenty feet long, and there would be a division in between here that would be five hundred feet long and in the neighborhood of two hundred feet wide. We had to put a man at the front and one at the tail end, and a pilot and a cook and two helpers. When your Wisconsin raft got down to Dubuque they got paid off, a dollar a day and your board.

The men on a raft were two men, the bowman and the tailman. When we went through the rapids we would disconnect the rafts. The Wisconsin rafts were made in three strings.

Two men on a whole raft, but when you ran through the dams or the rapids, then the rafts would be divided, be disconnected. You would have to divide them into three parts. They would consist of seven cribs. When we would go through the rapids there were no extra men hired, because they were taken from the other rafts. When we got to Dubuque, there we required less help. Formerly our raft would be 120 feet long, now she became possibly 620 feet, and we would only have two men to one string, no matter how long it was.

Testimony of John Starr

John Starr related that he made his first trip down river starting from Mehans Mill on the Wisconsin River and located about half way between Biron and Stevens Point. He ran lumber for the next fifteen years thereafter and the last trip was in 1888 and in the views of "rafting" John Starr is in the group with John Daly's crew.

Usually they started in May. This late date was given as necessary for the green lumber to dry out from the winter cut. Mr. Starr was head bowsman. There were different stages of water on the Wisconsin River. After June freshets the water would be very low, and difficult to get over sand bars, when they got stuck on sand bars he said, "We would swing one or two pieces out into the current and if that didn't carry off the bar then we would hold it until the water would back up".

"When we got down in the lower part of the Wisconsin River we spent much time getting the rafts off the sand bars. On trip in particular, we had trouble from Portage to Green River. That is about eighteen miles from the mouth of the river. In order to save handspiking and so we would not get stuck, the pilot went on ahead and staked out the channel for us, and we would run by those stakes. That avoided handspiking. We would go down five or six miles and land, then walk back for the half, and then tie up late in the evening. That is the way we worked it all the way down until we got to the mouth of Green River. The last eighteen miles we got along all right.

All I ever saw was this boat from Sauk to Portage; the Alvin Hardy. That was the only boat I saw on all of my trips down there, except that government boat, that was building those wing dams".

Testimony of Theodore W. Brazeau

Theodore W. Brazeau was next witness. "I was born in Wisconsin Rapids, which was then Grand Rapids; a place I think then of about eight hundred inhabitants, with three or four saw mills; and the principal industry was lumbering.

At an early age I learned to swim in the river, and spent all of my boyhood along the banks of the Wisconsin River; riding on rafts over the rapids when they would let me stay on; walking on the log jams in the river; watching the men driving the logs over the rapids and in the river; watching the men raft; going on the rafts whenever they laid up on the Wisconsin River to get pieces of prune pie, dried apple pie, from the cook; swimming off of the rafts; riding the logs, learning to cuff logs, roll them; entering contests in that line when I was a boy, on the 4th of July and other times.

I fished all along the river when I was old enough to carry a fishline in my pocket, and turned over the stones to get thunder bugs, as we called them, and fished for bass, suckers in season. I went down the river in a boat as far as Kilbourn with some boys, and camped on the banks. I went up the river above Biron and fished and camped. I was about thirteen or fourteen years old. I saw the rafts before that time and saw the log driving, when I was old enough to go down to the river. In those days they didn't pay as much attention to boys as they do now; they had no made playgrounds, whirligigs, or anything like that; and we made our sport in and along the river.

I knew the river from above Biron in those early days, where I used to go fishing, to some distance below Nekoosa. In the river above Biron there were some rapids called Crooked Drive, which were very shallow, very bad; but the rocks were not as large and as rugged as they were down below; but it was bad enough.

When you got to Biron there was a saw mill there and a dam; and there were rocks and rapids below that; and there were slides to let the rafts through; slides with fingers, that they constructed. They could get up to Biron without the slide and the dam and the fingers. The dam was twelve or eight feet high at that time, built in 1839, according to historical records.

Then you came down, and shortly below Biron you came to what is known as the eddy. Speaking of the eddy, below there, there was a place where there was a still piece of water, between there and Big Island, rafts laid up after going through the Biron dam and the rapids to repair the pieces. There was always some grub or something that got loose, or something broke, and then they would gig back. They had what they called gigging cars. We used to get rides on the gigging cars. The old lumberjacks kind of liked the little boys and let us ride in the gigs into Biron. Gigs generally had three seats, and the men sat in those seats and went back up to take the next piece down.

Below Biron they ran what was the worst piece of rapids that I knew anything about; very, very bad. There was a fall of about one hundred feet in Wood County.

And that Wisconsin Rapids, then known as Grand Rapids, there was big rapids called Grand Rapids. That went over rocks which were very large. The stream was tortuous, and the rocks were rugged; impossible to navigate, or even go over with a raft without artificial help, so they built little wing dams. There was a couple of brush dams that threw the water into a narrow channel, and there was another place where they had a sort of crib dam.

When you got at what is known as German Rock, they had to turn twice through there to strike that narrow channel that they made by building on each side. Taking the rafts down through those rapids, they took them down during the high water, a good stage water. In low water it was impossible, and they took them over then with the wing dams and the chutes. These chutes were arranged with logs laid side by side, extending down a couple of hundred feet. On the end of those logs were fingers. Those fingers were like the fingers of a hand; and they were loose, so that they could float up and down with the water. They were fastened at the upper end, I thought, by chains, I am not sure; but they took whole trees, just trimmed the ends of the limbs of the trees; but the lower end floated down below, forming what they called a finger.

The rafts would go down over that, and onto the fingers and the fingers would sink a little, just enough to let the raft slide on the fingers. Without this arrangement they couldn't get over the Wisconsin Rapids at all. I doubt if they could get over a great many rapids.

After they got down below the rapids, the main rapids, they generally pulled it at the bridge at Wisconsin Rapids and laid up again. And sometimes they would pull in at the bridge, and the water would get away from them and they would stay there for a number of weeks, waiting for water to get below them. Then we would swim off of those rafts, eat off the cook shanty, and have a good time.

Then right below the bridge there was a place below there called Neeves Island, and there was a series of rapids there which were very bad, but not as bad as Grand Rapids. The rocks were not as high; but when the water was down you didn't have a good stage of water, you couldn't make it over there at all because the rocks are almost continuous. They are there yet. When they pull the head of South Side Dam down, those rocks are sticking up there, and you can't go down even in a row boat. I have tried it. I might have gone down with the water high there. You can hear the roar of that rapids for half a mile away. They couldn't get over those rapids in low water.

Then you came down and on the south side was what was known as Hurleytown then. There was a bad stretch in there, but a dam in there of some kind. Then, Port Edwards, they had a dam there, and you went through there on a slide with fingers, the same as the other.

Then we had Whitney Rapids at Nekoosa. At Port Edwards one time, when the slide got out of repair someway, they blew a hole in the dam, and turned the channel to go through there.

The rafting began as soon as they could get a good stage of water. It was carried on until the water subsided or they got all the lumber down. If they got hung up, they waited until the next stage of water.

When they got below Nekoosa, what is known as the Bayous, they began to strike sand bars. They struck sand bars all through -- between Adams County and Juneau County, for a long ways, sand bars in there, big and little; and in ordinary or low water you could not let a row boat through there without getting out and pulling it off, or taking your oar out and pushing off the sand bars.

When we got down to Kilbourn then we had a Dells to run; which is a narrow, tortuous course and, a great many fleets broke up on it, many men drowned; and a great many men drowned at Wisconsin Rapids, in log driving and rafting.

There had been no carrying of goods up and down the Wisconsin River. It was impossible to carry goods up and down the Wisconsin River. There was a limited carrying of material. It was limited in kind, it was limited in season, and it was historically limited. The only kind of traffic I ever saw, and that was one way, was lumber, logs and rafts. That was difficult, hazardous, expensive, great loss of the product, both of logs and of lumber. As soon as they could find any other way of carrying it, they quit.

If the river remained just as it was in 1888, you could do what we did then, if you wanted to spend enough money to do it, put it in the shape that it was in 1888, in 1889, somewhere along that time. Of course, there are dams all along the river now. They could float between the dams, but there is never going to be any lumber or logs floated on the Wisconsin River again, unless you spend millions and millions of dollars in building locks and dams, and things that would make it beyond any possibility.